North America's Largest Metal Forming, Fabricating, Welding and Finishing Event

Join us for the 2021 3D/Additive Manufacturing Showcase

3D/Additive Manufacturing has proven to be a formidable technology in the manufacturing industry. This year, FABTECH will feature a presentation showcase in the 3D/Additive Manufacturing Pavilion to provide access to information on this fast-growing technology. The showcase features industry-leading companies sharing 20-minute presentations on the latest in the Additive Manufacturing community. View detailed descriptions and times of each presentation below. Visit Booth A1220 to catch a presentation.

High Speed Extrusion and the Future of Manufacturing

The manufacturing industry is increasingly moving toward a leaner and more agile future enabled by additive manufacturing, and this shift will save billions through new economic and production models. To get to the future state of manufacturing will require companies to commit to continuous and unrelenting innovation to do things never done before.

That goal is what drove Essentium to launch the industry’s first true IDEX machine—the Essentium High Speed Extrusion (HSE™) 280i HT 3D Printer. Unlike other IDEX 3D printers on the market, the HSE 280i HT 3D Printer features true independent dual extruders whereby each head is fully independent on both the X and Y-axis. This enables manufacturers to produce parts with complex geometric shapes faster and cheaper than competition.

This session will teach you how to leverage the next generation of additive manufacturing to bring new capabilities to 3D printed parts and step into the future of manufacturing.

David Rieman

Applications Development Manager

Essentium

Additively Manufactured Robotic End-of-Arm Tools feat. Savage Automation

The use of additive manufacturing (AM) in the robotics and industrial automation industry is becoming more prevalent every day. Material handling solutions are highly customized to the end user and AM can be used to complement and address many of the shortcomings of traditional manufacturing methods like machining and pre-fab framing. End-of-arm tooling (EOAT) is just one of the many applications that can benefit greatly from AM through lightweighting, part consolidation, customization, cost reduction, and time to market. In this 20-min session, we will address the following:

- Why AM makes sense for robotic EOAT

- Benefits and limitations of AM

- How to combine AM with off-the-shelf components

- See real-world examples of additively manufactured EOAT

Transform Your Business Through 3D Printing Applications

Attend this session and hear how traditional manufacturers are integrating 3D printing as one of the processes into their overall production. We’ll share how manufacturers are creating end-to-end digital supply chains and why there’s a growing interest to use AM for serial production of mid-sized series as well as for mass customization. Learn from Materialise’s three decades of 3D printing experience as one of the leading innovators with the largest 3D printing facilities and group of software developers in the world.

Moving 3D Printing from Prototyping to Mass Production

With part costs, build speeds, accuracy, surface finish and material properties finally rivaling conventional manufacturing methods, additive manufacturing (3D printing) is disrupting the traditional manufacturing of end-use parts.

Recent advances in additive manufacturing of metals and polymers (and even wood!) have made mass production a reality for a broad range of industries and applications. Additive manufacturing is ushering in a new era of mass-customized products that are lighter, greener, featuring new levels of complexity – built without tooling, and an inventory of one.

In this talk, we will cover:

- Recent breakthroughs across printing systems and materials

- Mass production case studies

- Selection criteria when choosing an AM solution

Tangible Use Cases of Additive Technologies in Metal Tubing, Forming and Welding

The uses of additive technologies when working with metal can be both indirect through printing typically plastic manufacturing aids for various processes and manufacturing stages as well as direct through directy producing complex metal components with metal additive manufacturing. Our application expert will give you insight into tangible use cases on production and assembly operations and examples of how to tailor jigs, fixtures, profile gauges, and locators to specific processes and components and quickly iterate for continuous improvement without costly traditional tool making and burdensome inventory costs. For metal working companies who are looking for thorough functional improvements or fast prototypes of thin walled parts, metal additive manufacturing use cases will show you how flow improvements and part consolidation are enabled.

David Cullen

Application Innovation Group

3D Systems

High Temperature Process with 500°C preheating

Additive manufacturing is seen as being one of the major revolutionary industrial processes of the next few years. Every technology has its own challenges and so does Additive Manufacturing. This presentation will expand upon the new developments addressing current challenges of metal additive manufacturing. New ideas as high temperature preheating a have a beneficial impact on this technology and are enabling the technology to increase the material portfolio. Steels with a significant carbon content can be manufactured with a high material quality. Titanium alloys don’t need to be massively supported because of reduced residual stress. This showcase will show how the 500°C preheating will impact the manufacturing process and enable Ti64 to be used for high volume applications.

Roland Spiegelhalder

Product Manager, Additive Manufacturing

TRUMPF

How to Leave Your Mark With Advanced Metal AM

Attend this session to learn how you can leave your mark in the metal AM industry. We will discuss the unique SupportFree additive manufacturing solution that provides engineers with the ability to unlock new designs, boost part performance, and lower part costs.

Zach Murphree

Vice President of Sales

VELO3D

From Challenge to Challenger: Leveraging Additive Manufacturing Strengths to Succeed

Additive Manufacturing (AM) has its challenges and strengths. If AM is not aiming to replace conventional manufacturing why adoption of this technology is growing so rapidly? Why some companies scale additive production faster than others? How can your organization become AM leader? Disruption is constant. Additive Manufacturing (AM) offers opportunity for agile manufacturing and innovation that is critical for thriving in continuously changing environment.

In this presentation, we will discuss how to work past AM challenges, how to explore its full potential from the ground up, and how to become a true innovator in your industry.

The first step is to look inward at your organization. It involves an end-to-end rethinking of your design process, your manufacturing philosophy, and your entire value chain. You’ll need agile teams that aren’t bound by traditional ways, and your organization must be set up to nurture and optimize that agility. With the right organizational groundwork, you will create new opportunities for your products and your business that will grow more powerful over time.

Why a 3D Printer is A Must-Have Tool in Your Workshop in 2021

3D printing technology can feel unapproachable and challenging to learn, but a 3D printer can play a transformative role in your workshop at an accessible cost and with minimal training. Join Kathy Bui of Formlabs to learn how 3D printing empowers fast, flexible manufacturing of jigs and fixtures, prototypes, spare parts and more. She’ll also provide insight on how to leverage 3D printing in alternative workflows like low-volume injection molding, carbon fiber layup, and electroplating. Kathy will discuss key business needs, like assessing when to bring 3D printing in-house and how to empower anyone with CAD proficiency to take full advantage of a 3D printer.

You’ll walk away with a high level view of the most popular 3D printing technologies and how they can become an excellent addition to your workshop in 2021.

Machine Learning and Advanced Digital Gauging for Subtractive and Additive Manufacturing Processes

Artificial intelligence and machine learning are of increasing interest and applicability to industrial manufacturing enterprises. The potential to accelerate the transition to automated work-flows via incorporation of sophisticated computational algorithms has already been leveraged in the field of design engineering for some time. In this presentation, we will be considering how the combination of simulation, in-situ measurement and machine learning can pay real-time dividends to both well understood subtractive manufacturing processes and nascent additive manufacturing technologies. In the course of the work presented, Altair (Troy, MI) a world-leading software and cloud solution provider for simulation, IoT, high performance computing (HPC), data analytics, and artificial intelligence (AI) teamed up with Renishaw (Gloucestershire, UK) a global leader in industrial metrology, healthcare and additive manufacturing (AM).

Transform Your Business Through 3D Printing Applications

Attend this session and hear how traditional manufacturers are integrating 3D printing as one of the processes into their overall production. We’ll share how manufacturers are creating end-to-end digital supply chains and why there’s a growing interest to use AM for serial production of mid-sized series as well as for mass customization. Learn from Materialise’s three decades of 3D printing experience as one of the leading innovators with the largest 3D printing facilities and group of software developers in the world.

Hyperion Metals: Developing low-cost, low-to-zero carbon spherical titanium metal powders for use in 3D printing

Hyperion Metals has the exclusive rights to a breakthrough American technology that can produce low cost, low-to-zero carbon titanium metal and spherical titanium metal powders.

These patented technologies were invented by Dr. Z. Zak Fang at the University of Utah and have been advanced from a lab-scale technology to full pilot plant production scale over a six year development program. This development program was funded by the Advanced Research Projects Agency – Energy (“ARPA-E”) of the U.S. Department of Energy.

Hyperion Metals wants to deliver a sustainable all-American, closed-loop solution for customers that will include:

-

-

-

- Superior product: titanium metal is an ideal metal for advanced manufacturing applications due to the highest strength-to-weight ratio of any metal and superior corrosion resistance

- Low-cost: Hyperion aims to produce titanium metal at cost-parity with stainless steel. At cost-parity, titanium will achieve clear superiority, driving adoption and opening use cases beyond today’s high-value titanium parts

- Low-to-zero carbon: low-to-zero carbon production process using 100% renewable energy, replacing the industry’s incumbent carbon-intensive Kroll process

- Closed-loop recycling: proprietary technologies that can recycle existing titanium metal feedstock with the same zero carbon process at the required quality specifications

- Transparent and traceable supply chain: vertically integrated all-American supply chain with full visibility from the Tennessee minerals all the way to the finished titanium metal

-

-

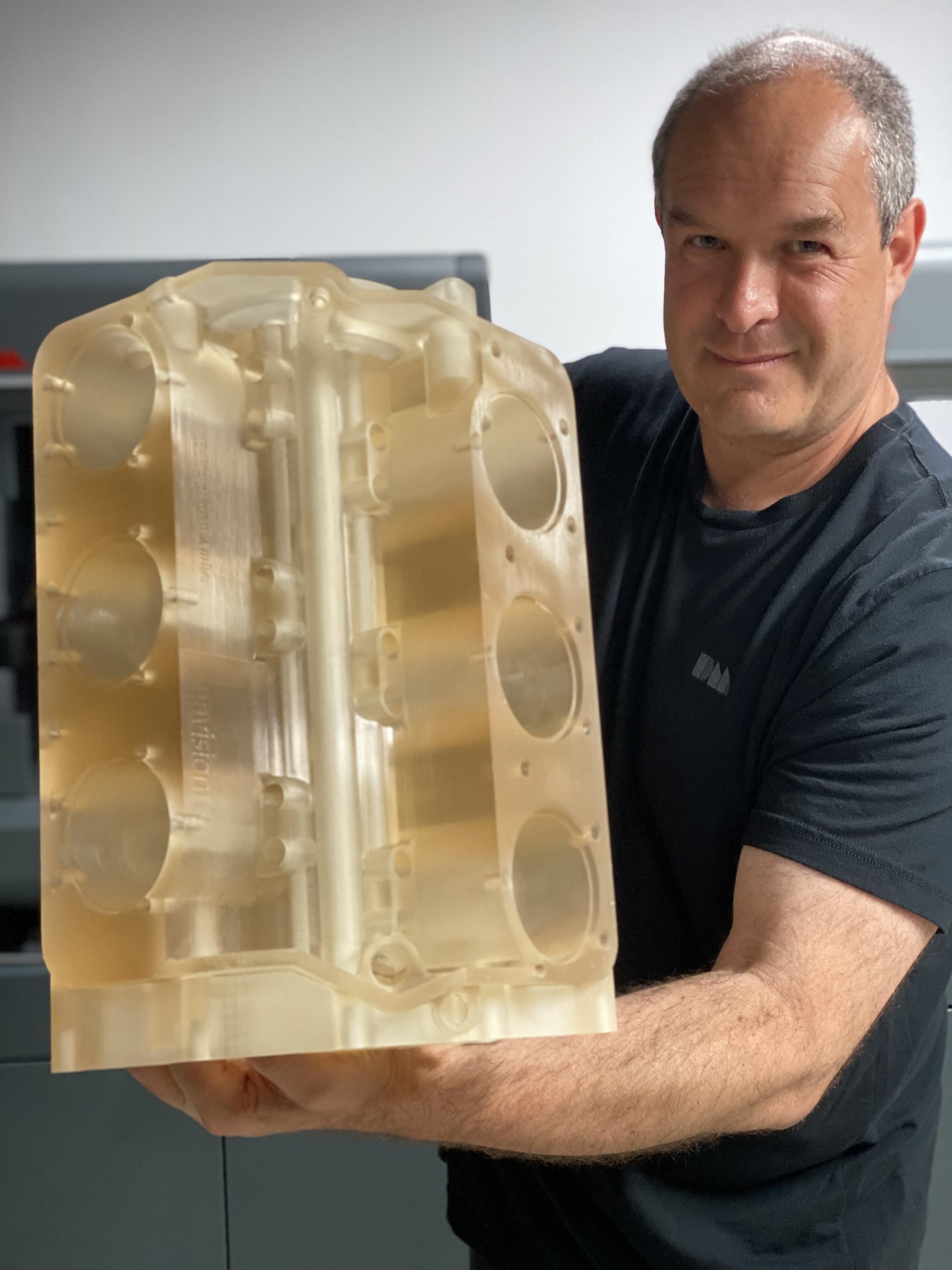

Tangible Use Cases of Additive Technologies in Metal Tubing, Forming and Welding

The uses of additive technologies when working with metal can be both indirect through printing typically plastic manufacturing aids for various processes and manufacturing stages as well as direct through directy producing complex metal components with metal additive manufacturing. Our application expert will give you insight into tangible use cases on production and assembly operations and examples of how to tailor jigs, fixtures, profile gauges, and locators to specific processes and components and quickly iterate for continuous improvement without costly traditional tool making and burdensome inventory costs. For metal working companies who are looking for thorough functional improvements or fast prototypes of thin walled parts, metal additive manufacturing use cases will show you how flow improvements and part consolidation are enabled.

David Cullen

Application Innovation Group

3D Systems

Value Added Capability of HP Metal Jet

Three-dimension (3-D) printing offers the ability to expand design freedom, simplify manufacturing processes and reduce processing time. Now, with a new 3D printing technology for metal parts, the HP Metal Jet process continues to push the boundaries of efficiency, design (parts consolidation, topology optimization, etc.), and customization in a mass production environment to enable applications in automotive, medical, industrial, and 3Cs (computers, cell phones, and consumer electronics) industries. This presentation discusses how the above value-added capabilities of the Metal Jet process enable mass production.

Customizing Materials for Additive Manufacturing Applications: Opportunities and Challenges

Additive Manufacturing offers end users unique advantages over conventional manufacturing technologies. A major advantage is the lower cost of capital investment required to go from idea to working prototype. This also makes the technology perfectly designed for high value, short run, customized production applications (medical, wearables, jigs and fixtures, etc.). However, these types of applications often require specific material performance attributes for end use application that require customization to achieve. The complexity material requirements coupled with the plethora Additive Manufacturing technologies and equipment present major challenges for technology proliferation in end use parts. This talk will discuss these challenges in greater detail and present some opportunities and strategies to potentially overcome these issues.

Dr. Jeffrey J. Cernohous

Chief Operating Officer and Member

Interfacial Consultants, LLC, a Nagase Group Company

From Challenge to Challenger: Leveraging Additive Manufacturing Strengths to Succeed

Additive Manufacturing (AM) has its challenges and strengths. If AM is not aiming to replace conventional manufacturing why adoption of this technology is growing so rapidly? Why some companies scale additive production faster than others? How can your organization become AM leader? Disruption is constant. Additive Manufacturing (AM) offers opportunity for agile manufacturing and innovation that is critical for thriving in continuously changing environment.

In this presentation, we will discuss how to work past AM challenges, how to explore its full potential from the ground up, and how to become a true innovator in your industry.

The first step is to look inward at your organization. It involves an end-to-end rethinking of your design process, your manufacturing philosophy, and your entire value chain. You’ll need agile teams that aren’t bound by traditional ways, and your organization must be set up to nurture and optimize that agility. With the right organizational groundwork, you will create new opportunities for your products and your business that will grow more powerful over time.

Space Application – Thrusters

Additive Manufacturing, known colloquially as 3D Printing, is now an established method of manufacturing, is real and not a gimmick. We are currently in a new space race, which is being led by commercial tech start-ups. These companies are small, nimble-acting and forward-thinking, refuse to do things the old way and embrace the new. For these companies and more, Additive Manufacturing is the key to unlocking access to space. As we seek to push the boundaries of human space flight, the challenge for space launch providers and the associated supply chain, is to provide greater access to space by improving products, deploying new materials, simplifying designs, decreasing part count, reducing errors and driving smarter and leaner operations. From combustion devices for rocket engine propulsion to DED additive manufacturing of domes, barrels and fuel tanks, the technology is providing real solutions to space exploration problems. This showcase will elaborate on space applications made from non-standard AM materials.

Roland Spiegelhalder

Product Manager, Additive Manufacturing

TRUMPF

The Intersection of Advanced Technology and High-Quality Materials

Essentium’s High Speed Extrusion (HSE™) 3D platform gives manufacturers the speed, strength, and scale to handle the most demanding applications. However, as a materials-first company, Essentium knows that real innovation happens when advanced technology meets high-quality materials.

The HSE 280i HT 3D Printer is the first industrial 3D printer to offer true IDEX, where each head is fully independent on both the X and Y-axis. This technology not only allows users to speed up support printing, but it also unlocks multi-material 3D printing for users to blend material properties at print speeds and part strengths never seen in additive manufacturing.

This session will showcase Essentium’s newest advanced materials and the applications that multi-material printing can unlock.

Industrial Post-Processing of 3D-Printed Metal Parts

Dr. habil. Wolfgang Hansal

Managing Director

RENA Technologies Austria GmbH

FABTECH Speakers

Richard Savage

Owner, Savage Automation

Richard Savage, the owner of Savage Automation, has 15 years of injection molding experience, working on and with all types of molds, molding machines, and molding automation. He founded Savage Automation in 2017 to bring robust design and cutting edge technology to End of Arm Tooling, while simplifying its installation and operation.

Liz Stortstrom

Application Engineer, HP 3D Printing

Liz Stortstrom is a 3D Printing Application Engineer (AE) with expertise in using HP’s Multi Jet Fusion (MJF) Technology for industrial applications. She has a background in Mechanical Design and joined HP to support the development of the MJF technology. She now utilizes that experience to help people take their businesses to the next level with additive manufacturing. Liz received her BS & MS in Mechanical Engineering from Carnegie Mellon University and currently resides in Portland, OR.

Dave Flynn

Business Development Manager, Manufacturing Solutions, Materialise

Flynn has 28 years of experience in the additive manufacturing industry. Prior to joining Materialise in 2013, Flynn founded two large additive manufacturing bureaus that he operated for more than 20 years.

Ilya Mirman

Chief Marketing Officer, Desktop Metal

Ilya is Chief Marketing Officer at Desktop Metal. Prior to joining Desktop Metal, he ran marketing at SolidWorks, and venture-backed startups including Onshape, Drift, and Turbonomic. Earlier in his career, he led the product development and manufacturing teams at Corning-Lasertron to introduce a new line of high-speed laser transmitters for the telecom industry.

Ilya holds a BSME from the University of Massachusetts, an MSME from Stanford University, an MBA from MIT’s Sloan School, and several patents in the field of fiber optic communications. In his free time, he enjoys concert photography.

Maryna Ienina

AM Consultant – Digitalization, EOS North America

Maryna is an Additive Minds Consultant in Digitalization at EOS. She supports integration of EOS systems into existing manufacturing infrastructure and use of machine sensor data to optimize utilization of industrial 3D Printing. She also coordinates activities for Additive Minds Academy and facilitates digitalization of AM education.

Maryna earned her master’s degrees in mechanical engineering from Texas A&M University, Korea Institute of Science and Technology (KIST), and the National Technical University of Ukraine Polytechnic Institute. At KIST she did research about the flexible floating ring seal that is used to reduce air leakage and increase compressor efficiency. She started her journey in additive manufacturing in July 2016 as an Applications Engineer.

Now together with EOS Additive Minds she shares her expertise to help in leveraging innovation with industrial 3D Printing.

Kathy Bui

Product Lead, Engineering Business, Formlabs

Kathy holds a bachelors of science in Materials Science and Engineering from MIT and an MBA from ESADE business school. She joined Formlabs in 2018, managing Formlabs’ materials product portfolio, ensuring they deliver value to customers. Kathy currently heads up the Engineering Business Vertical at Formlabs, driving product strategy and applications development to better serve this segment. Prior to Formlabs, she worked as an engineer, product development lead, technical program manager, and product manager for various materials science startups from MIT.

Angkit Choudhury

Engineering Data Scientist, Altair

Angkit has a Master of Science in Electrical and Computer Engineering degree, focused on Applied Machine Learning/Deep Learning in Computer Vision and Natural Language Processing. He has performed research in machine learning and NLP applied to social media on tasks such as classification, sentiment analysis. Angkit joined Altair in 2017 and is currently working on applying Machine Learning/Deep Learning in developing data driven solutions in the fields of predictive/diagnostic analytics (IoT), CAE and high performance computing (HPC).

Kevin Brigden

Applications Engineer, Renishaw, Inc.

Kevin has a master’s degree in Engineering with honors in Motorsports Engineering from the University of Central Lancashire, England. He has been with Renishaw since 2014 working as an applications engineer in the Additive Manufacturing Products Division (AMPD). A member of a team of technical specialists, he brings a skill-set centered in Computer Aided Engineering (CAE) including: Computer Aided Design (CAD), Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD). During Kevin’s time with Renishaw, he has led and consulted on numerous design projects in collaboration with partners and customers from Aerospace, Automotive, Space and Defense, and Medical engineering. Kevin is at the forefront of the Design for Additive Manufacture (DfAM) movement, with many of his characteristic and innovative designs widely recognized and imitated.

Anastasios Arima

CEO and Managing Director, Hyperion Metals

Mr. Arima is a resource company executive with a strong history of identifying company-making resource projects. He was the founder and former Director of Piedmont Lithium (ASX:PLL) and was instrumental in identifying and securing the Piedmont Lithium Project. He has extensive experience in the formation and development of energy and resource projects in North America and Europe. He attended the University of Western Australia where he earned a Bachelor of Commerce while studying for a Bachelor of Engineering.

Josh Carroll

New Product Introduction Engineering Lead, Parmatech

Josh Carroll is the New Product Introduction Engineering Lead at Parmatech. Josh joined Parmatech in 2013. Josh has spent his time at Parmatech developing products using both Metal Injection Molding and 3D Printing of Metal. Josh leverages his knowledge and experience in multiple technologies to guide Parmatech’s Partners and Stakeholders through the product design and development lifecycle. Josh earned a Bachelor of Science degree in Mechanical Engineering from the University of California Irvine.

Harish Irrinki

Applications Engineer, HP Metal Jet

Harish Irrinki is an Applications Engineer for HP Metal Jet technology with specialized expertise in the consumer electronics and aerospace industry. In this role, Harish leads the execution of customer engagement and market adoption strategies with a focused approach on applications and disruption opportunities for HP Metal Jet technology.

Previously, Harish was an Application Engineer for a startup company specializing in the metal 3D printing applications for thermal industry.

Harish graduated from University of Louisville with a Ph.D. in Mechanical Engineering focus in metal Additive Manufacturing. Harish has authored and co-authored several journal and presented his research findings in several international conferences.

Harish is based in Corvallis, OR.

Tom Mulholland, Ph.D.

Specialist Materials Engineer, Essentium, Inc.

Tom Mulholland is a Specialist Materials Engineer at Essentium, Inc. Tom received his Ph.D. in mechanical engineering from the University of Wisconsin – Madison where he studied plastics processing and additive manufacturing. Tom developed some of the first thermally conductive filaments for material extrusion AM and demonstrated its use in additive manufacturing of air-cooled heat exchangers. Previously, he worked for two years at the Institute for Training and Research in Plastics and Rubber (ICIPC) in Medellín, Colombia, collaborating on projects including injection molding, energy efficiency, and foaming. At Essentium, Tom works on new filament development projects, quality control, and materials evaluation, qualification, and testing.